Indlela yokunciphisa ukulahleka kwensimbi ekwakhiweni kobunjiniyela

Indlela ebaluleke kakhulu ukwazi isizathu sokusetshenziswa kwensimbi enkulu, noma ngabe ubukhulu bamandla bukabubulu buphezulu noma imvamisa kukhulu noma ukugcwala kwendawo kubaluleke kakhulu njalonjalo. Vele, ngokuhambisana nendlela ejwayelekile, ngakolunye uhlangothi, kuyadingeka ukulinganisa okungokoqobo okuningi ngangokunokwenzeka kusuka ohlangothini sekulingisa, ngakolunye uhlangothi, ubuchwepheshe bokuxhumana kwenqubo bunciphisa ukusetshenziswa kwensimbi okwengeziwe. Ngokusho kwendlela ejwayelekile ukwandisa ukusetshenziswa kwe-silicon yensimbi yensimbi enhle, ukuze izimo ezihlukile zohlelo zibe nokuhlukaniswa komkhiqizo okungcono.

1.I-MANUARTIMIDELWE YAMABA WAMABA

Ukwenza kahle umjikelezo kazibuthe, ukwenzela kahle izakhiwo ze-sinusoidal zensimu kazibuthe. Lokhu kubucayi kakhulu, hhayi kuphela kuma-motors wokungenisa ama-frequency-frequency. I-Effect Frequency Ukungeniswa kwe-Motor Synchronous motor ibalulekile. Ngake ngenza ama-motors amabili ngokusebenza okuhlukile ukuze kuncishiswe izindleko emkhakheni wemishini yezindwangu, Yebo, into ebaluleke kakhulu ukuthi akukho lutho oluthambekele, oluphumela ekungathobeki kwe-sinusoidal ye-Air Calpess Callen. Ngoba umsebenzi usezingeni eliphakeme kakhulu, ukusetshenziswa kwensimbi kubangela ukuba kukhulu kakhulu, ngakho-ke ukulahleka kwama-motors amabili kukhulu kakhulu, futhi ekugcineni, ngemuva kokusetshenziswa kwe-motor ngaphansi kwama-algorithm angaphansi kwamahlandla ama-2. Kukukhumbuza futhi ukuthi lapho wenza isivinini sokuguqulwa kwejubane lemvamisa, kufanele uhlanganise i-algorithm yokulawula ukukwenza.

2.decrese Magnetic density

Indlela ebaluleke kakhulu ukwazi isizathu sokusetshenziswa kwensimbi enkulu, noma ngabe ubukhulu bamandla bukabubulu buphezulu noma imvamisa kukhulu noma ukugcwala kwendawo kubaluleke kakhulu njalonjalo. Vele, ngokuhambisana nendlela ejwayelekile, ngakolunye uhlangothi, kuyadingeka ukulinganisa okungokoqobo okuningi ngangokunokwenzeka kusuka ohlangothini sekulingisa, ngakolunye uhlangothi, ubuchwepheshe bokuxhumana kwenqubo bunciphisa ukusetshenziswa kwensimbi okwengeziwe. Ngokusho kwendlela ejwayelekile ukwandisa ukusetshenziswa kwe-silicon yensimbi yensimbi enhle, ukuze izimo ezihlukile zohlelo zibe nokuhlukaniswa komkhiqizo okungcono.

3.Ukulinganisa umjikelezo kazibuthe

Ukwenza kahle umjikelezo kazibuthe, ukwenzela kahle izakhiwo ze-sinusoidal zensimu kazibuthe. Lokhu kubucayi kakhulu, hhayi kuphela kuma-motors wokungenisa ama-frequency-frequency. I-Effect Frequency Ukungeniswa kwe-Motor Synchronous motor ibalulekile. Ngake ngenza ama-motors amabili ngokusebenza okuhlukile ukuze kuncishiswe izindleko emkhakheni wemishini yezindwangu, Yebo, into ebaluleke kakhulu ukuthi akukho lutho oluthambekele, oluphumela ekungathobeki kwe-sinusoidal ye-Air Calpess Callen. Ngoba umsebenzi usezingeni eliphakeme kakhulu, ukusetshenziswa kwensimbi kubangela ukuba kukhulu kakhulu, ngakho-ke ukulahleka kwama-motors amabili kukhulu kakhulu, futhi ekugcineni, ngemuva kokusetshenziswa kwe-motor ngaphansi kwama-algorithm angaphansi kwamahlandla ama-2. Kukukhumbuza futhi ukuthi lapho wenza isivinini sokuguqulwa kwejubane lemvamisa, kufanele uhlanganise i-algorithm yokulawula ukukwenza.

4.Decrese Magnetic density

Khulisa ubude be-Iron Core noma ukhuphule indawo yokuvuselela kazibuthe yesekethe kazibuthe ukunciphisa ubuningi be-flux kazibuthe, kepha inani le-iron elalisetshenziswa yimoto lizokhula ngokufanele;

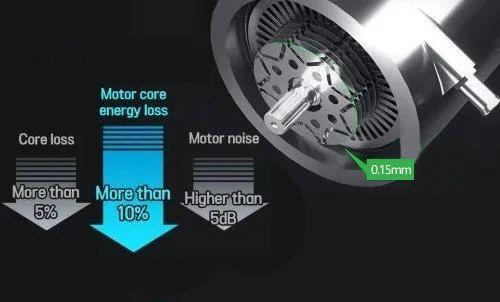

5.REDEUCE Ubukhulu be-Iron chip ukunciphisa ukulahleka kwamanje

Uma ishidi lensimbi elibandayo le-silico lisetshenziswa esikhundleni seshidi lensimbi ye-silicon eshisayo, ubukhulu beshidi lensimbi le-silicon bungancishiswa, kepha ishidi elincane le-iron core lizokwandisa inani lama-iron chips kanye nezindleko zokukhiqiza zemoto.

6.Ishidi lensimbi elibandayo elibandayo elinama-magnetic afanelekile asetshenziselwa ukunciphisa ukulahleka kwe-hysteresis

7.High New Iron I-Chip Chip Insulation Coang

8.Heat Heath Technology

9.Ingcindezi esele ngemuva kokuthi umshini we-iron chip uzokuthinta kakhulu ukulahleka kwemoto, kanye nesiqondiso sokusika nokushaya ukucindezelwa kwe-shear kunethonya elikhulu ekulahlekelweni yimishini yensimbi ye-silicon. Ukusika eceleni kwendlela yokugoqa ye-silicon yensimbi eshidini lokushisa kweshidi lensimbi ye-silicon spching kunganciphisa ukulahleka kwe-10% kuya ku-20%.

Isikhathi sePosi: Nov-27-2023